How to Identify and Install CAN Bus Contactless: Complete Guide

🎯 Who is this article for: GPS installers, telematics technicians, mechanics, and anyone who needs to identify or connect to a vehicle's CAN bus.

Need to identify the CAN Bus cables of a vehicle? Want to know how to measure CAN-H and CAN-L with a multimeter? Looking for a way to read CAN Bus data without cutting cables?

In this guide I explain everything you need to know: how to identify CAN cables, what voltages you should measure, and how contactless technology works for non-invasive reading.

What is Contactless CAN Bus Connection?

The contactless CAN Bus connection allows reading CAN bus data from a vehicle without cutting, splicing or connecting cables directly to the CAN-H and CAN-L lines.

It works through inductive coupling: the device is placed around the CAN cable and detects the electromagnetic signals traveling through it.

Difference from Traditional Connection

| Aspect | Traditional Connection | Contactless Connection |

|---|---|---|

| Installation | Direct splice to CAN-H/CAN-L | Inductive board with zip ties |

| Installation time | 30-60 minutes | 5-15 minutes |

| Invasiveness | Cable cutting | No cuts |

| Vehicle warranty | May affect it | Doesn't affect it |

| Risk of damage | Medium (connection errors) | Very low |

| Transmission (write) | ✅ Yes | ❌ Read only |

| Compatibility | Universal | Requires accessible cable |

How Does Contactless CAN Bus Work?

The CAN Bus system transmits data through differential signals between two wires: CAN-H (High) and CAN-L (Low). These signals create a small electromagnetic field around the cable.

A contactless reader detects this field using an inductive board. The CAN cables are placed close to the board and secured with zip ties, without cutting or splicing anything. The board amplifies the signal and converts it into data that the GPS device can process.

Advantages of Contactless Connection

1. 🔧 Ultra Fast Installation

Installation is reduced to placing the CAN cables close to the board and securing them with zip ties. No need to:

- Identify polarity (CAN-H vs CAN-L)

- Strip cables

- Make splices

- Use heat shrink tubing

Average time: 5-15 minutes vs 30-60 minutes for traditional connection.

2. 🛡️ No Warranty Risk

By not modifying the vehicle's original wiring, the manufacturer's warranty remains intact. This is critical for:

- Fleets with leased vehicles

- New vehicles under warranty

- Customers requiring non-invasive installations

3. ⚡ Lower Risk of Errors

The most common errors in traditional CAN Bus installations are:

- Reversing CAN-H and CAN-L

- Poor splices generating noise

- Accidental short circuits

With contactless, these errors are impossible because there's no direct electrical connection.

4. 🔄 Easy Reinstallation

Need to move the device to another vehicle? With contactless you simply remove the zip ties and place it on the new vehicle. No cut cables or splices left behind.

When to Use Contactless Connection?

✅ Ideal for:

- Light vehicles (cars, pickups, SUVs)

- Fleets with active warranty

- Quick installations (high volume)

- Leased or rented vehicles

- Cases where you only need to read data (speed, RPM, consumption)

⚠️ Traditional connection is better when:

- You need to send commands to the vehicle (remote immobilization via CAN)

- The CAN cable is not accessible (some vehicles have sealed bus)

- Heavy vehicles with multiple buses (J1939 in trucks may require direct connection)

- Very tight budget (contactless module has additional cost)

🛠️ Installing a Contactless Reader

If you've already identified the CAN cables and decided to use a contactless reader, here are the general installation steps:

1. Locate the CAN Cable

1. Locate the CAN Cable

The CAN cable is generally found in:

- OBD-II port (under dashboard, driver side)

- Behind the dashboard (requires panel removal)

- Engine compartment (in some European vehicles)

💡 Tip: Look for a cable with two twisted wires (typically green/white or orange/brown depending on manufacturer).

🔧 How to Detect CAN-H and CAN-L with a Multimeter

Before installing any CAN Bus device, it's essential to correctly identify the CAN-H and CAN-L cables. Here's how to do it with a common multimeter.

CAN Bus Voltage Values

The CAN protocol uses differential signals. This means CAN-H and CAN-L have complementary voltages:

| Bus State | CAN-H | CAN-L | Difference (H - L) |

|---|---|---|---|

| Recessive (idle) | 2.5V | 2.5V | 0V |

| Dominant (transmitting) | 3.5V | 1.5V | 2V |

| Average with activity | ~2.5-3V | ~2-2.5V | ~0.5-1V |

⚡ Important: These measurements are with the engine running and the vehicle in operation. With ignition off, voltages may be 0V.

Measurement Procedure

Step 1: Prepare the Vehicle

- Start the engine (or at least turn ignition on)

- Let electronic systems activate

- The CAN bus should be transmitting data

Step 2: Configure the Multimeter

- Set multimeter to VDC mode (DC voltage)

- Range: 20V or auto-range

- Black probe → GND (vehicle ground)

- Red probe → cable to measure

Step 3: Measure CAN-H to GND

CAN-H MEASUREMENT

- Multimeter: VDC

- Black (COM): Vehicle ground

- Red (+): Suspected CAN-H cable

Expected reading: 2.5V - 3.5V (fluctuating with bus activity)

If you read ~2.5V to 3.5V → It's probably CAN-H ✅

Step 4: Measure CAN-L to GND

CAN-L MEASUREMENT

- Multimeter: VDC

- Black (COM): Vehicle ground

- Red (+): Suspected CAN-L cable

Expected reading: 1.5V - 2.5V (fluctuating with bus activity)

If you read ~1.5V to 2.5V → It's probably CAN-L ✅

Step 5: Differential Measurement (optional but recommended)

To confirm, measure the difference between both cables:

DIFFERENTIAL MEASUREMENT

- Multimeter: VDC

- Black (COM): CAN-L

- Red (+): CAN-H

Expected reading: 0V - 2V (fluctuating rapidly)

If reading fluctuates between 0V and 2V → You confirm it's the CAN bus ✅

Quick Diagnostic Table

| Measurement | CAN-H vs GND | CAN-L vs GND | Diagnosis |

|---|---|---|---|

| Engine running | 2.5-3.5V | 1.5-2.5V | ✅ CAN bus active |

| Engine off | 0V | 0V | ⚠️ Normal, start engine |

| Both ~12V | 12V | 12V | ❌ Not CAN, it's power |

| Both 0V with engine on | 0V | 0V | ❌ Not CAN or damaged bus |

| One 5V, other 0V | 5V | 0V | ❌ Possible digital signal, not CAN |

Typical CAN Cable Colors

| Manufacturer | CAN-H | CAN-L |

|---|---|---|

| VAG (VW, Audi, Seat, Skoda) | Orange/Brown | Orange/Black |

| Ford | Yellow | Green |

| GM (Chevrolet) | Yellow | Green |

| Toyota | Light Blue | White |

| Fiat/Stellantis | Green | White or Orange |

⚠️ Warning: Colors may vary by model and year. Always verify with multimeter before connecting.

⚠️ Important: OBD-II Protocol is REQUEST-Based (on-demand)

The OBD-II connector has pins 6 (CAN-L) and 14 (CAN-H) for the high-speed CAN bus. However, there's a very important consideration:

🚨 The OBD-II Protocol is REQUEST-Based (on-demand)

Unlike the vehicle's native CAN bus that constantly broadcasts data, the OBD-II bus only transmits data when queried. This means:

- Without a diagnostic tool connected → The bus is silent (0V or idle voltage)

- With an active diagnostic tool → The bus transmits responses

For this reason, you won't see any activity on the multimeter if you only connect to OBD-II without sending queries.

Where to Measure Then?

To detect the CAN bus with constant activity, look for the vehicle's native CAN bus:

- Behind the dashboard - Vehicle modules (ECU, ABS, BCM) are constantly communicating

- In the engine harness - There's permanent CAN traffic

- Direct connection to modules - Any module connected to the main bus

The native CAN bus continuously transmits data (speed, RPM, temperature, etc.) without needing queries, so you'll always see activity with the engine running.

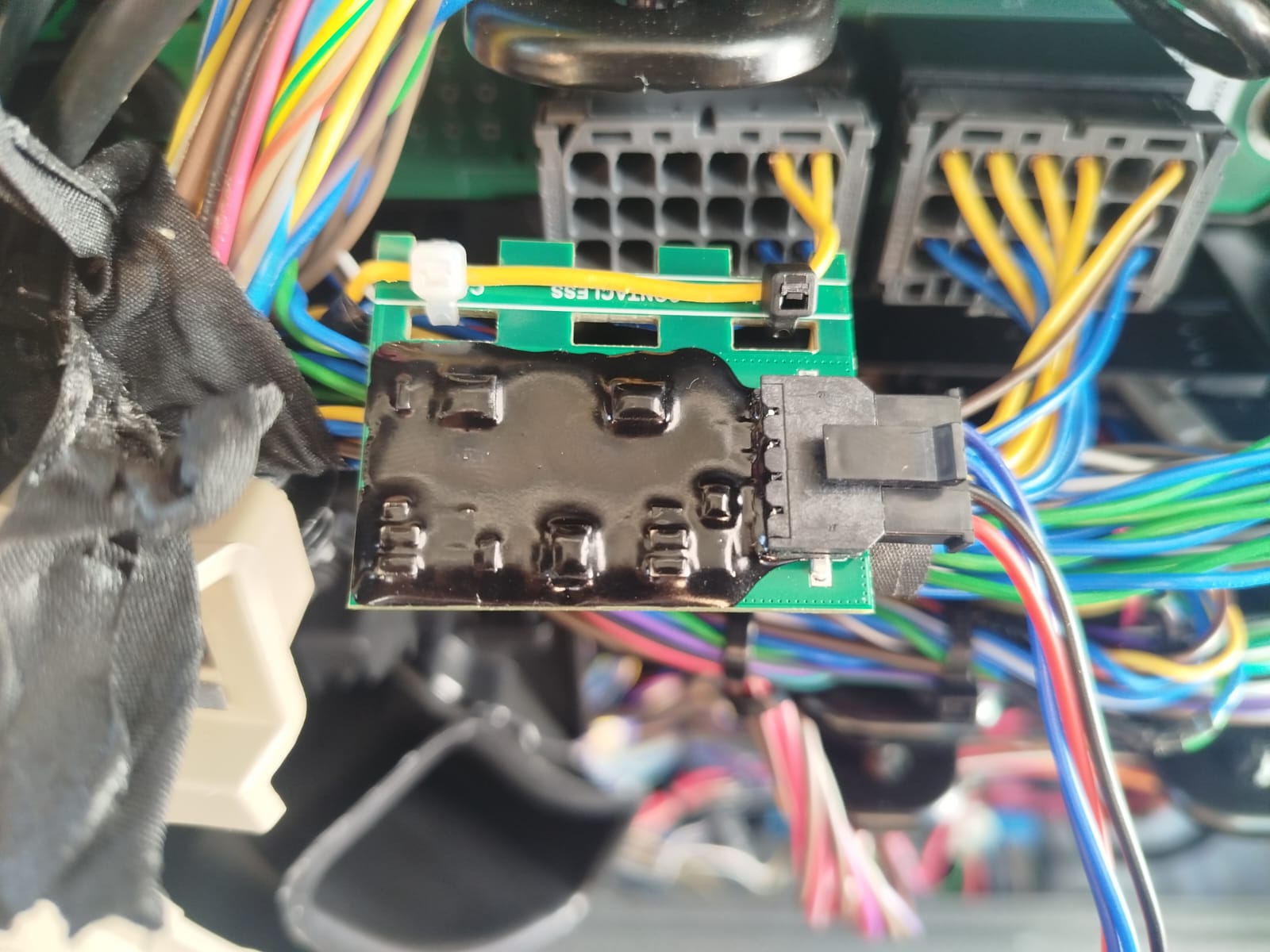

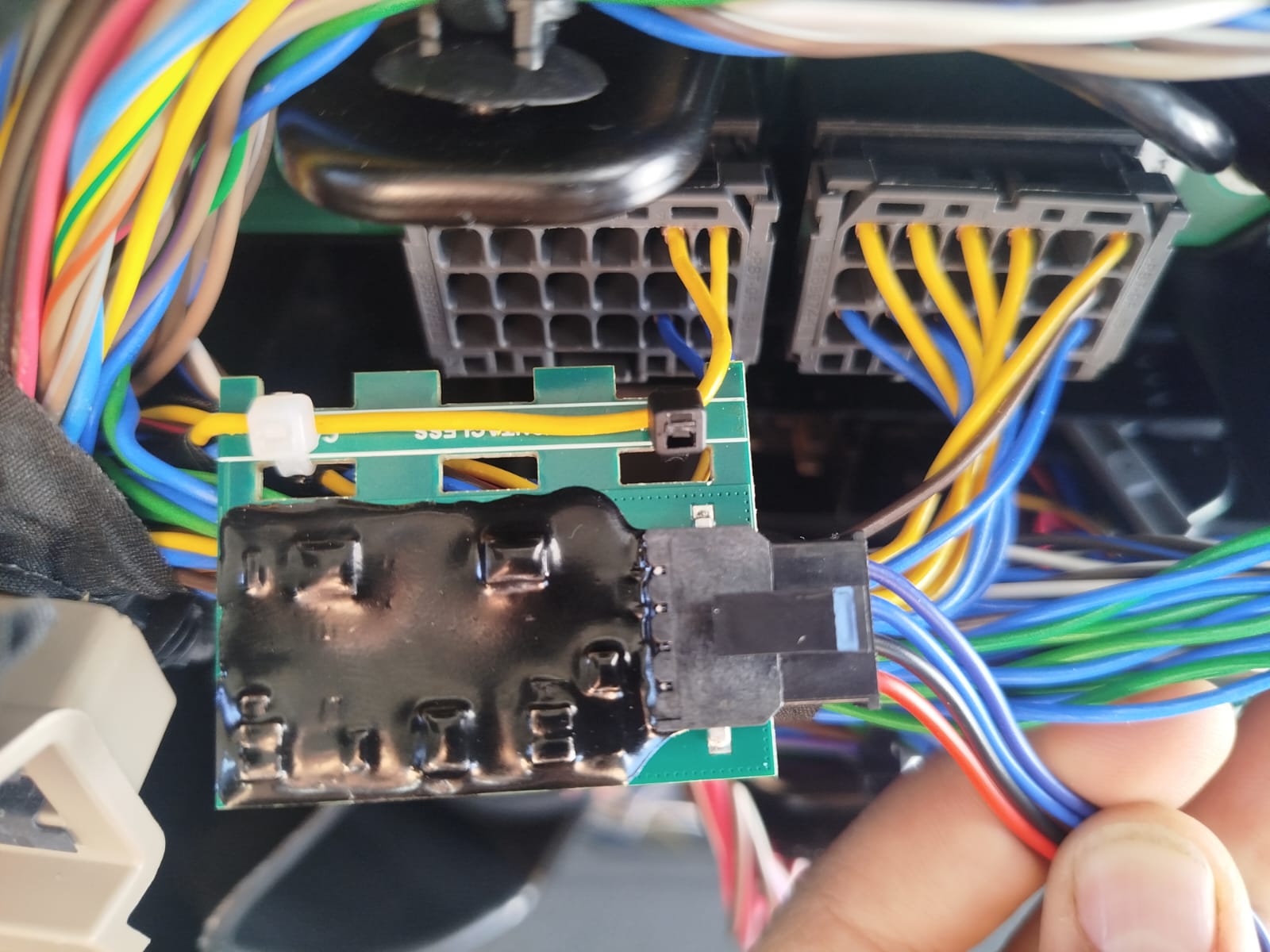

Contactless Installation Example

Here's how a contactless module looks installed:

CAN cables are placed close to the inductive board and secured with zip ties

CAN cables are placed close to the inductive board and secured with zip ties

Installation on wiring harness - cables secured to the board without cuts

Installation on wiring harness - cables secured to the board without cuts

Contactless module connection to GPS device

Contactless module connection to GPS device

2. Secure Cables to the Board

- Identify the CAN cables (two twisted wires)

- Place the cables close to the inductive board

- Secure them with zip ties so they stay in contact with the board

- Make sure the zip ties are tight

3. Connect to GPS Device

- Connect the contactless module cable to your GPS or telematics device's CAN port

- Configure the device for contactless CAN mode (check your manufacturer's documentation)

- Verify data reading on the platform

4. Verify Operation

On the tracking platform you should see:

- ✅ Vehicle speed

- ✅ Engine RPM

- ✅ Fuel consumption

- ✅ Engine temperature

- ✅ Fault codes (DTC)

Frequently Asked Questions

Does it work with all vehicles?

It works with most vehicles after 2008 that use standard CAN Bus. Very old vehicles with proprietary protocols may not be compatible.

Can I read the same data as with direct connection?

Yes, in read mode you get exactly the same data. The only limitation is that contactless doesn't allow writing to the bus (sending commands).

Does it affect vehicle operation?

No. Being read-only and without electrical connection, the contactless module is completely transparent to the vehicle.

What happens if the cables come loose?

If the cables move away from the board, reading is interrupted but there's no risk of damage. Simply reposition them and secure again with zip ties.

Comparison: Contactless or Traditional?

| Scenario | Recommendation |

|---|---|

| Fleet of company cars on lease | Contactless ✅ |

| Trucks with J1939 requiring immobilization | Traditional |

| Massive installation (100+ vehicles/month) | Contactless ✅ |

| Own vehicle without warranty | Traditional (more economical) |

| Customer requiring no vehicle modification | Contactless ✅ |

| Very limited budget | Traditional |

Conclusion

Contactless CAN Bus connection is a technology that greatly simplifies telematics device installation, especially in:

- ✅ Fleets where warranty is important

- ✅ High volume installations

- ✅ Vehicles that shouldn't be modified

If your case requires read-only data (which is 90% of fleet management applications), contactless is the safest and fastest option.

For cases where you need to send commands to the vehicle or budget is very tight, traditional connection remains an excellent alternative.

Additional Resources

More about CAN Bus:

- What is CAN Bus? - Introductory guide to the protocol

- CAN Data Capture with CXECU - Advanced configuration tutorial

Rinho's Contactless Solution:

If you're looking for a professional contactless module, the Rinho CANBUS Contactless supports CAN 2.0A, CAN 2.0B, J1939 and OBD-II protocols, speeds up to 1 Mbps, and works with Smart IoT, Spider IoT and Zero IoT GPS devices.

📖 Complete technical documentation: docs.rinho.com.ar/canbus

Have questions about CAN Bus identification or contactless installation? Write to us and we'll help you.